Magneto Conversion

This article is intended for members who for some reason or other, find themselves without a magneto or who are not satisfied with the performance of their magneto. The advantage of this is that the original advance/retard mechanism can be retained. An old magneto can be used.

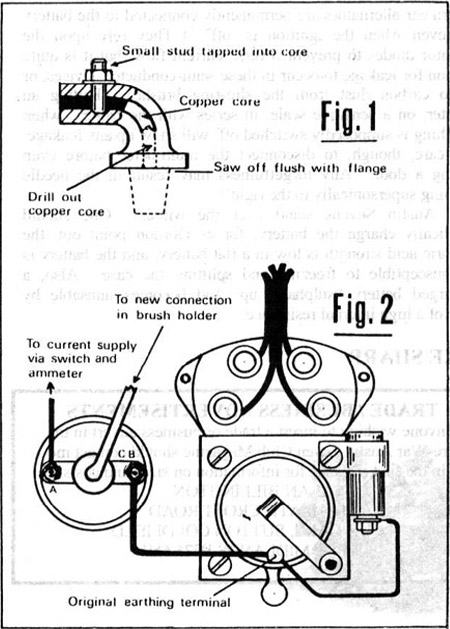

Dismantle magneto making sure to mark the armature and distributor gear wheel teeth, If they are not already marked, to ensure correct position on reassembly. Cut out the armature windings to decrease load on nial-ncto bearings, and re-assemble, packing bearings with grease. The slip ring brush holder must now be modified as in Fig. 1. Drill out the copper core, as Indicated, as there is a danger of arcing if this In not done. For the same reason, it is advisable to dispense with the cover plate.

Fix a Coil Of correct voltage to a convenient position. e.g. tool compartment door, or Inside tool compartment. Connect a lead from battery via Ignition switch to terminal A on coil. Prom terminal CB connect a wire to terminal on magneto end cap. Mount suitable condenser under end plate, screw an, ' connect another wire from condenser to terminal on end cap. (Fig. 2). Connect HT cable from coil to stud on modified slip ring brush holder and fit T.U. suppressor rear brush holder end. If the former magneto switch is used the earthing connection must be removed or a separate switch can be mounted in a convenient position. If the magnet from your car has been used, it can be assembled In its original position, and re-timing should not be necessary. Advance and retard can still be controlled from the manual control lever.

Article supplied by Secretary, Mike Harris.